Description

Overview

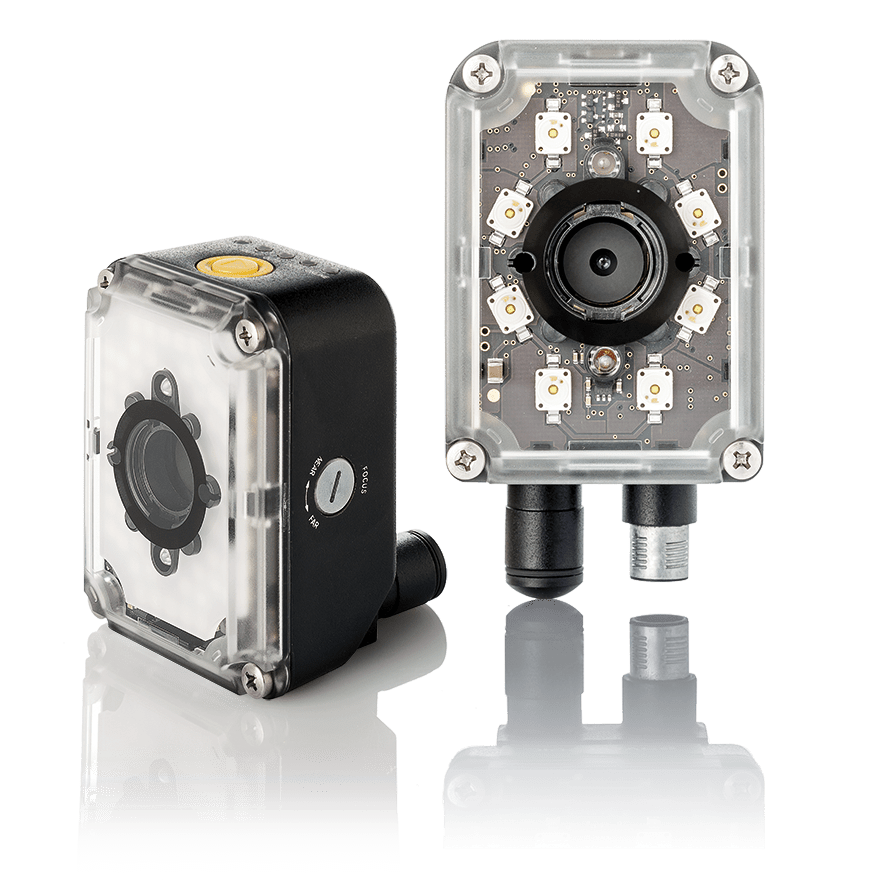

Matrix 320 image based code reader has been designed to EMPOWER TRACEABILITY

applications providing benefits for End Users and Machine Builders. Matrix 320

brilliantly solves traceability applications in Intralogistics, Distribution, 3PL, Retail

logistics and the Shop Floor.

Matrix 320 offers a COMPLETE SOLUTION and TOP PERFORMANCE to achieve higher

productivity at the best price/performance ratio with its superior 2MP sensor (1920 ×

1080 pixels with a 16:9 form factor), achieving an extra large Field of View (FOV) on

horizontal axis that competes against 3MP readers.

Matrix 320 has excellent reading performance on label and high resolution DPM with a

powerful Smart configurable lighting allowing 3 color options able to solve extremely

challenging traceability applications. To boost productivity in Intralogistics and Logistics

segments, hands-free operations enjoy higher performance with Matrix 320 snappy

reactivity and its outstanding Depth of Field (DOF).

Matrix 320 provides the highest market application flexibility with a modular design, a

reduced number of models complemented by a complete portfolio of lenses, lightings,

filters, and accessories.

Embedded electronic focus for the Liquid Lens models dramatically reduces

installation time and allows easy reconfiguration improving production flexibility in

line with Industry 4.0 requirements. Matrix 320 is very easy to install with its improved

integrated aiming system, X-Press button HMI and DL.Code software powered by easy

and intuitive autolearning/autosetup features.

APPLICATIONS

Manufacturing

• Direct Part Marking Reading

• Component and Part Traceability

• Wip Traceability (Automatic)

• Print & Apply

• Secondary Packaging Traceability

Manufacturing, Transportation and Logistics, Retail

• Inbound, Pallet Picking (Fork Lift)

• Print & Apply verification (Re-labelling)

• Depalletizing, Part Traceability

• Order Fulfillment (Automatic, Manual)

• Palletizing (Automatic, Manual), Cage Preparation

• Pallet Traceability, Pallet Wrapping

• Retrieval for outbound (Forklift)

Technical Specification

| 14 LED Illuminator Model | 36 LED Illuminator Model | |||

|---|---|---|---|---|

| Sensor | Image resolution 2.0 Mpixel (1920 x 1080) 16:9 form factor – 1/3” CMOS global shutter | |||

| Frame Rate | 60 frames/s | |||

| LIQUID LENS MODELS | ||||

| Reading Range | 6mm: Minimum: 50 – Maximum: 550 mm 9mm: Minimum: 35 – Maximum: 1000 mm 16mm: Minimum: 70 – Maximum: 1500 mm | |||

| Optical Models (Viewing Angles) | Liquid Lens 9 mm (34°), Liquid Lens 16 mm (20°) | |||

| Optical Focus Control | Electronic focus control | |||

| Illumination | Internal illuminators colors: Blue, Red, White lights (only for Liquid Lens 9 mm and16 mm) | |||

| C-MOUNT MODELS | ||||

| Optical Models (Viewing Angles) | C-Mount Lens 4mm(68°), 6mm(48°), 8mm(37°), 12mm(25°), 16mm(19°), 25mm(12°), 35mm(9°) | |||

| Optical Focus Control | Manual focus adjustment | |||

| Illumination | Internal illuminators colors: Blue, White, IR, UV | |||

| Polarizing Filter | Available as front cover accessory | |||

| Code Quality Metrics | 1D CQ Standard: ISO/IEC 15416 2D CQ Standard: ISO/IEC 16022/18004, ISO/IEC 29158 (AIM-DPM), ISO/IEC 15415 | |||

| Power Supply | 24 VDC ± 10% | |||

| Max Power Consumption | 0.42 A, 10 W max | 0.62 A, 15 W max. | ||

| Protection Class EN60529 | IP65 and IP67 | |||

| Operating Temperature | Liquid lens models: -0 to 45°C / 32 to 113 °F C-MOUNT models: -10 to 50°C / 14 to 122 °F | |||

| Storage Temperature | -20 to 70 °C / -4 to 158 °F | |||

| Case Material | Aluminium case and plastic protective window cover | |||

| Dimensions | H 108.7 x W 54 x L 55.5 mm / 4.3 x 2.1 x 2.2 in Connector at 0° H 88 x W 54 x L 75.6 mm / 4.3 x 2.1 x 2.2 in Connector at 90° | H 115.5 x W 126 x L 70.3 mm (4.6 x 4.9 x 2.8 in) Connector at 0° H 101 x W 126 x L 90.7 mm (4.6 x 4.9 x 2.8 in) Connector at 90° | ||

| Weight | Liquid lens 14 LED illuminator: 380 gr (13.4oz) | Liquid lens 36 LED illuminator: 650 gr (22.9oz) | ||

| Sulfur Gas Resistance | Available for all models according to ISO EN 60068-2-43 | |||

| Sulfur Gas Resistance | Available for all models according to ISO EN 60068-2-43 | |||

| ESD Safe | Available as front cover accessory | Not Available | ||

| YAG Laser Protection | Available as filter accessory (compatible with ESD cover) | |||

| Embedded Communication Interfaces | – Ethernet 10/100/1000 Mbit/s: TCP/IP, UDP, FTP, SFTP and Fieldbus PROFINET IO, Ethernet IP, Modbus TCP – Serial RS-232/RS-422FD up to 115.2 Kbit/s + Serial Aux RS-232 up to 115.2 Kbit/s – OPC UA | |||

| Reader Networking | Datalogic ID-NET™ | |||

| Connectivity Modess | Pass Through, Master/Slave, Ethernet point to point | |||

| Digital Inputs | 2 inputs opto-coupled and polarity insensitive Max. Voltage 30 VDC Max. Input Current 10 mA | |||

| Digital Outputs | 3 Outputs: configurable NPN, PNP and PP short-circuit protected VOUT (ILOAD = 0 mA) max. 24 VDC VOUT (ILOAD = 100 mA) max. 3 VDC ILOAD max. 100mA Using CBX connection box the first 2 outputs are opto-coupled | |||

| Aiming System | Laser cross red projection aiming | |||

| User Interface | Configurable 360 degree multicolor visual feedback Green spot and Red spot LEDs X-PRESS™ Human Machine Interface Beeper, X-PRESS™ Push Button, 7 LEDs (Status, Communication , Trigger, Good Read, Ready, Power on, Network) Web Monitoring Interface | |||

| Device Programming | DL.CODE™ Windows-based software (programming via Ethernet or Serial Interface) with Javascript output formatter Serial Host Mode programming; X-PRESS™ Human Machine Interface | |||

| Warranty | 2-Year Factory Warranty | |||

Let us know your requirements

Just send us your questions we will give

you the help you need.

you the help you need.

Reviews

There are no reviews yet.