Adhesive and Sealant Inspection

The inspection of adhesives and sealants (typically applied as beads) is

a critical quality control step in the assembly of electronics. To meet this

challenge, Gocator all-in-one 3D smart sensors offer a complete solution

to ensure correct bead volume and location without overflow or breaks.

Welcome To Datasensor

As a leading distributor of Industrial Automation products

Datasensor Started in 1984 (India), it was established by Dr. N Chandrashekhara in Bengaluru, Karnataka. As a leading distributor of industrial automation products, Datasensor represents many leading companies such as Datalogic, Micro Detectors, Teledyne Dalsa and Neousys to name a few.

Create new products, reduce cost and risk, and enable the manufacturing. Innovations enabled by the Steeler institutes results in products that assist workers, make buildings safer, consume less energy. There are many variations of passages of Lorem Ipsum available but the majority have suffered that a alteration in that some form by injected .

Harry Oliver,

CEO of Steeler Industrial

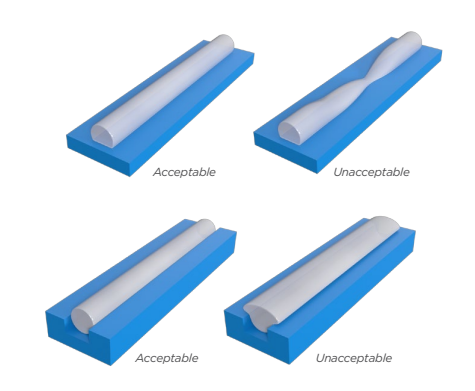

The Application

Adhesives and sealants are used in a wide range of applications

in consumer electronics. Whether they are applied as

continuous or individual beads, it is important to verify correct

volume and location before moving to the next assembly step.

Excess volume can result in leakage and rejection of the final

part. Alternatively, insufficient or broken beads can lead to poor

adhesion or seal and premature failure as a result.

The Implementation

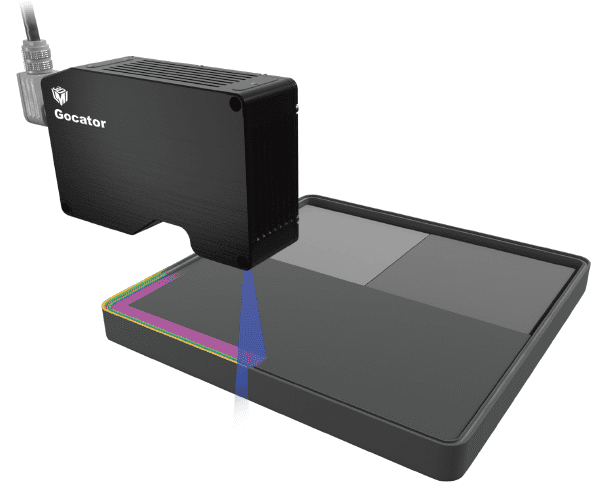

A Gocator line profiler is mounted on a robot or dispenser to scan the adhesive

or sealant after it is applied to open or groove-filled surfaces. Scanning after

dispensation ensures the beading is properly applied and within the correct

tolerance.

Gocator provides built-in measurement tools to set up automatic pass/fail

requirements. These tools can detect excessive coating, dents/gaps, or flaws

(incorrect position). For example, to calculate the correct position of the

adhesive bead, the width between the bead and the edge of the part can be

measured using the Surface Dimension tool (top image) at chosen locations.

Additional measurements, such as height, length, and angle can be applied to

ensure adherence to desired shape. In Profile mode, the sensor calculates the

amount of material applied using the Profile Area tool (bottom image). This

can be achieved continuously in real-time and produce multiple profile crosssections along the target.

Built-in measurement tools, including Surface

Dimension and Profile Area for calculating bead

volume and location

The Benefits of 3D

2D technology cannot be used for adhesive and sealant

inspection because 2D images are unable to distinguish

transparent glues from the surrounding area. Gocator 3D

smart sensors provide features for scanning materials

that vary from transparent to opaque, including multiple

exposure and automatic top surface detection.

In addition, 2D is unable to measure height data and

volume. Gocator 3D smart sensors, in comparison,

provide high-resolution height data, which allows users

to accurately determine bead location and volume.

Let us know your requirements

Just send us your questions we will give

you the help you need.

you the help you need.