Hole and Fastener Inspection

Drilling holes and applying fasteners are critical processes in

today’s aerospace manufacturing sector. To ensure the quality

of key components, tight controls must be maintained. The

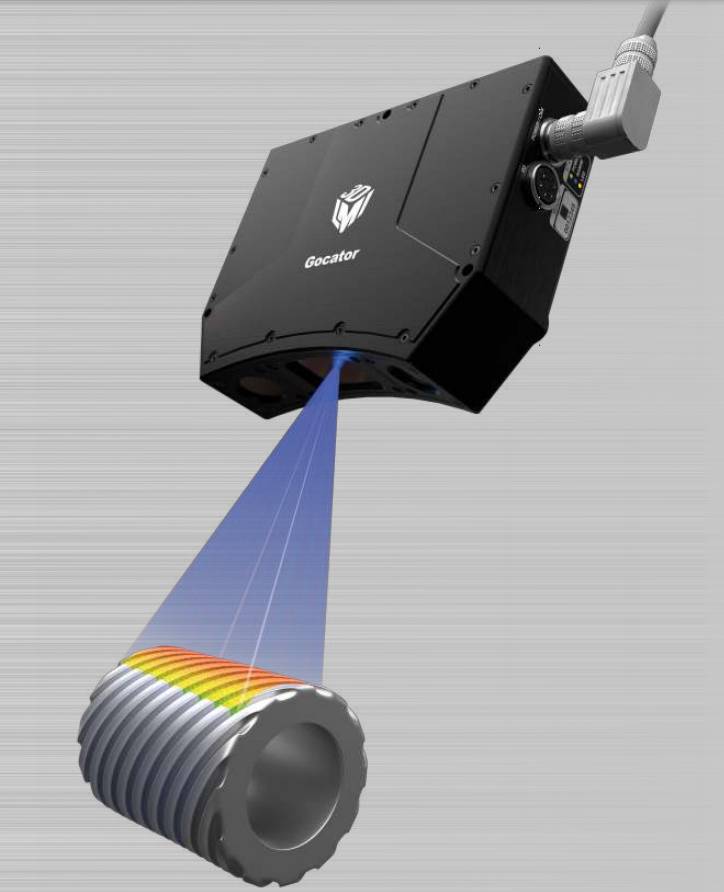

Gocator 3000 series snapshot sensors offer a complete

solution for this important two step application.

The Application

Countersunk holes drilled into curved parts and assemblies

(such as airplane fuselages) must meet tight tolerances. The

Gocator 3000 series snapshot sensors can be mounted on

robotic systems and used to quickly scan and analyze the hole

geometry.

After the holes are verified, fasteners (such as rivets) are

inserted to join components together. These fastener heads

need to be inspected for flushness, gap and angle in relation

to the surrounding surface in order to ensure the quality of

each join.

Thousands of fasteners can be required in the assembly of a

plane and checking each fastener manually is time-consuming

and error-prone. Gocator 3000 series is a powerful automated

solution for this inspection challenge.

The Implementation

For hole inspection, a Gocator 3210 sensor, mounted to a robotic system, moves

to a group of holes drilled into a piece of material and quickly scans them with a

single 3D snapshot. Multiple instances of the built-in Countersunk Hole tool return

a set of measurements for each hole, including inner and outer radius, depth, and

counterbore.

For fastener flushness inspection, multiple Gocator 3506 sensors are mounted

onto robot arms. As a fuselage or other component moves into a station, the

sensors move close to the surface to scan the fasteners. The built-in Surface

Fastener tool returns measurements on and around the fastener. This tool can

account both for fasteners that protrude and are set too deeply. It also has the

ability to measure other types of fasteners, such as flat heads and dimpled heads,

as well as fastener buttons on the underside of the material.

The Benefits

Gocator snapshot sensors offer a complete 3D quality control

solution for this critical two step inspection process

Gocator 3210’s reliable, accurate measurements (down to

35 µm) help ensure the smallest deviations from strict

tolerances are caught with every scan, reducing the risk of

costly mistakes. In addition, the Gocator 3210 sensor’s high

speed and large FOV let you quickly measure multiple holes

and/or fasteners in a single scan, saving your organization time

and money.

Gocator 3506 offers a smaller FOV with even higher resolution

(down to 12 µm) so you can meet the strict tolerances required

on small holes and fasteners. Similarly, the sensor’s high speed

lets you scan one or more features in less than half a second,

so you can quickly determine if intervention is necessary

Let us know your requirements

Just send us your questions we will give

you the help you need.

you the help you need.